3PEAT will invest on the following technologies and integration platforms:

- Passive optical polymers - 3D PolyBoard™

- Si3N4/SiO2 platform - TriPleX™

- InP elements - TriPleX™

- 3D PolyBoard™ - TriPleX™

Passive optical polymers – 3D PolyBoard™

FhG-HHI has developed a single-mode polymer platform (PolyBoard™) for multi-functional PLCs. Structures that can be monolithically integrated include among others low-loss waveguides (<0.5 dB/cm), MMI couplers, tunable couplers, 90o optical hybrids, Bragg-gratings, DIs, VOAs, Optical FlexLines and AWGs. Using the platform as an optical integration bench, filters and polarization elements such as PBS and polarization rotators can also be integrated, whereas hybrid integration of lasers, gain chips and photodiodes is also supported. Moreover, FhG-HHI has explored the possibility for stacking multiple polymer layers on a silicon substrate via the repetition of the fabrication steps, and has recently demonstrated a 3D structure with a total of 19 waveguides in 5 different layers.

3PEAT aims to further upgrade PolyBoard™ by developing a solution for the transition of light from a waveguiding layer to a different one within a multilayer structure, based on the use of vertical MMI couplers. The development of this solution will act as the key enabler for the development of a fully functional 3D PolyBoard platform with the same features and integration capacity per layer, as its standard 2D counterpart.

Si3N4/SiO2 platform - TriPleX™

LioniX has developed a single-mode, high contrast, ultra-low loss platform (TriPleX™) which is compatible with high volume production processes. TriPleX™ is based on alternating SiO2 and Si3N4 layers, enabling the fabrication of very compact photonic circuits. Thermo-optically tunable micro-ring resonators with tight bending radii can be fabricated on this platform and will be used as MZI switches for building optical switching modules.

3PEAT aims to further upgrade TriPleX™ by heterogenously integrating PZT layers on top of the platform, using an optimized pulsed layer deposition process, and realizing in this way ultra low power consumption PZT PZT phase shifters with high speed (operation up to 50 MHz), ultra-low power consumption (200 µW/π-phase shift at 1 kHz), short length (<2 mm) and low polarization dependence.

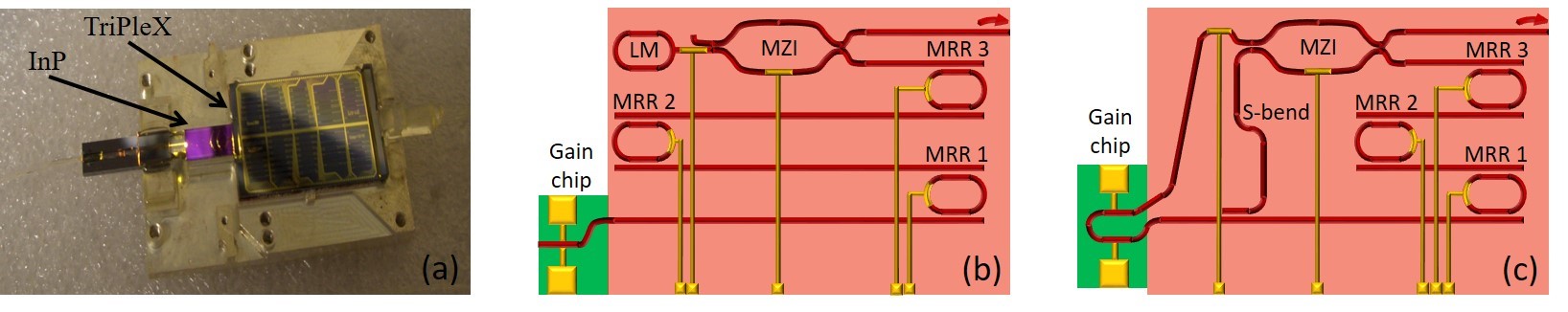

Integration of InP elements and TriPleX™

InP gain chip butt-end-coupled to TriPleX. (b) Laser design on TriPleX with linear (standing-wave) cavity and target linewidth <1 kHz. (c) Ring laser design with intra-cavity S-bend, and potential for narrow linewidth (100 Hz) and tolerance to reflections. 3PEAT will fully develop the first design, and will study the second one as a possible extension.

A disruptive laser source in the form of an integrated external cavity laser with linewidth in the sub-kHz regime will be enabled by the low propagation loss (<0.1 dB) and the possibility for micro-ring resonators (MRRs) with high Q-factor on the TriPleX platform, which can enable in turn the construction of very long and highly selective cavities. The active element of the source will be an InP gain chip that will be integrated with the TriPleX part using butt-end-coupling techniques.

An InP gain chip will be integrated with a TriPleX part using butt-end-coupling techniques in order to develop a disruptive laser source in the form of an integrated external cavity laser with linewidth in the sub-kHz regime. This performance will be enabled by the low propagation loss (<0.1 dB) and the possibility for micro-ring resonators (MRRs) with high Q-factor on the TriPleX platform, which can enable in turn the construction of very long and highly selective cavities.

Integration of 3D PolyBoard™ and TriPleX™

An advanced integration engine will be developed for joining the two platforms and realizing the 3PEAT hybridly integrated platform. Leveraging the possibility to spin-coat the polymer material in almost every surface and have precise control on the thickness and the pattern of the spin-coated layers, the process will continue with the spin-coating of the polymer resin inside the etched area. The coupling between the waveguides will be in-plane and will be optimized using alignment markers and tapered waveguide sections in the TriPleX part.